Nuevo cabezal de corte láser.

En LANTEC 2000 acabamos de adquirir un nuevo cabezal de corte láser.

Este sistema de corte láser se ha instalado en nuestras instalaciones de Orcoyen y nos da la posibilidad de realizar cortes de precisión mediante un sistema de seguimiento asegurando la distancia entre la boquilla y la pieza a cortar sin tener que copiar manualmente toda la superficie.

Soldadura láser de extintores

Nuevos ensayos para la parametrización de soldadura láser en la fabricación de extintores.

Se llevan a cabo ensayos en Lantec para parametrizar la soldadura láser de dos cachas de inoxidable que han de conformar un extintor.

Leer más

Automation process for laser marking of components for the hardware industry

We are running a new project to automate a laser marking process for one of the most important hand tool maker in Europe.

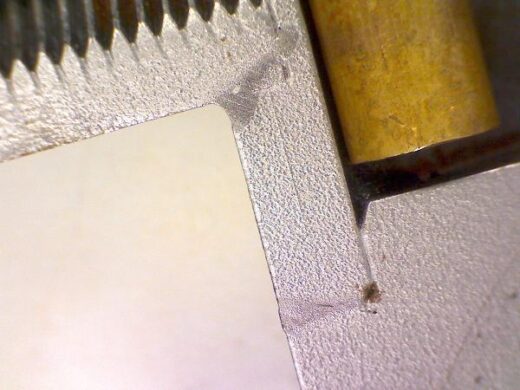

Laser marking over covered cast steel

Lantec, laser system manufacturer, is running several test to check feasibility of a laser marking system on hand tool, black painted in one case and chromed in the other.

Leer más

Tests of laser welding on bronze and stainless steel

At Lantec laser we are developing a series of tests of laser welding on bronze and stainless steel, trying to achieve balance, stability and above all quality in the solutions we offer.

Electrical battery laser welded

Lantec to start production of a new series of components for batteries focused on electric automobile.

Electrical battery laser welded

Lantec to start production of a new series of components for batteries focused on electric automobile.

New try out to test laser welding control system

Lantec is running a test to prove reliability of 4D Weld Watcher system. According to the manufacturer, partially ionized metal vapour is created during laser welding, cutting or soldering.

Leer más

New test is carried out in Lantec to consolidate process of laser welding.

In this case we are laser welding 0.3 thick Alu plates together.

First tries are done preparing butt welding tool with good results at 1.2 m/min. However tensile test results are giving low values for the expected target.

Secondly, overlap (0.3 + 0.3) welding shots are produce, lowering power and using 600 w pulsed power laser.

Leer más

Laser welding applied to the manufacture of cutting discs

Recently we have investigated the manufacture of diamond cutting discs in our laser welding laboratory. Discs are used mainly in the construction field, allowing clean and quick cuts in a wide range of materials. They are constructed by a serrated disc, with a hardened outer zone, usually with diamond.

Laser welding station for automotive component

New laser welding machine to be manufactured in Lantec for automotive industry component production.

Aluminium laser welding for electricity conduction

Tests to define the conditions and parameters of laser welding in aluminum parts for applications where some significant amount of electric current may be required.

New process is going on in Lantec to define parameters for HIPS material.

Customer requires a clean and fast cut to go forward with the investment. State of the art has not reach both levels at the same time invalidating any chance of industrialization.-

Welding laser procedures

Welding metal pieces, in order to joint components, is a common solution in our customer’s procedures.

New Ophir Photonics calorimeter

Lantec 2000 has purchased an OPHIR Photonics calorimeter to verify power output and fiber alignment from the resonator to the optical output.

High thickness laser seam welding

In this two 3mm steel parts laser seam welding test, a 4.5mm penetration has been achieved by using 4kw fiber laser and D50 optical fiber. The welding speed is 20mm/sec.

New fixture for laser welding of automobile components

New fixture is been tested on Lantec.

When talking about laser welding of automobile components fixture becomes together with the laser election the critical issues that you need to control.

New application for laser is tested in our premises

Our customer wants to check whether laser welding is able to produce a reliable joint in bearing cartridges manufacturing, producing a in this case, we are using a CO2 slab laser of 2.5 Kw with a Precitec welding head, welding at a speed of 1 m per minute, searching for maximum penetration without affecting the inner diameter of the shaft.

New macrograph to prove high reliable joint on steering support

Test to be done after shows over 1 KN to traction resistance. By using a 3.5 Kw fiber laser on a remote welding process, customer satisfaction has been guaranty in terms of joint quality.

New laser welding station for automotive component

Lantec to install new laser welding station in Mexico for automotive component.

Lantec just purchased a new scan head form Raylase

This scan system will be installed in our premises of Orcoyen and will give us the chance to proceed with high power remote welding.